Van Brienenoord Bridge, The Netherlands

Embracing

a circular

approach

Sabine Delrue

Director, Infrastructure

Scroll to explore

A game-changing idea takes sustainability to the next level for essential infrastructure.

Next-generation sustainability

Bridges are essential to the highways network in the Netherlands for decades. One of the busiest bridges in the country is the Van Brienenoordbrug, a key connection to the Port of Rotterdam, carrying about 230,000 vehicles daily. It exemplifies the challenge facing the Dutch government and many others globally – so many bridges built decades ago now need renewing. How do we repair and extend the lifespans of such important infrastructure assets? How can it be done safely, sustainably and without excessive disruption? Working closely with our client and partner, we found a way.

Mapping the natural frequencies of the double bridge, represented by two timbres, one for each side: one undergoing renovation and the other replacement, with traffic ‘crossfading’ to reflect the construction plan.

Audio experience

Map data ©2021 Google

Rejuvenating infrastructure, bridge by bridge

We began work on a bridge renovation programme in 2009, collaborating closely with the national highway authority Rijkswaterstaat and our partner RHDHV. Over 12 years we designed the renovation of seven steel bridges, strengthening and upgrading existing structures rather than building new ones. This focus on refurbishment minimised waste, reduced the volumes of new materials needed for construction, and cut the length of time bridges had to be closed to traffic.

Each bridge offered new insights into how to tackle the next, taking us towards the most complex challenge of them all. Part of the Netherlands’ busiest highway, the Van Brienenoord bridge comprises 12 lanes of traffic split across the eastbound bridge built in the 1960s and the 1990s western bridge.

A national icon

The Van Brienenoordbrug Bridge is a national icon and is one of the busiest bridges in the Netherlands

Explore Van Brienenoord in 360

Digital expertise, creative thinking

Our work on Van Brienenoord began with a monitoring programme that gathered 70 billion data points from nearly 100 sensors and cameras. This programme informed the calibration of both our structural and geometric models. The structural finite element model was calibrated through strain gauge measurements, while the BIM model used point cloud data to digitally duplicate the actual geometry.

An initial plan for renewing the Van Brienenoord bridge proposed the tried-and-tested option of strengthening with a concrete overlay. But nobody was truly sold on this, including our project manager, Daan Tjepkema. There were concerns about safety and lengthy disruption to traffic, so an alternative using steel plates was suggested. This, too, was rejected because such an innovative technique was untested at this scale.

Reducing carbon

The solution to reuse materials will extend the life of the bridge for another 100 years

An engineering brainwave

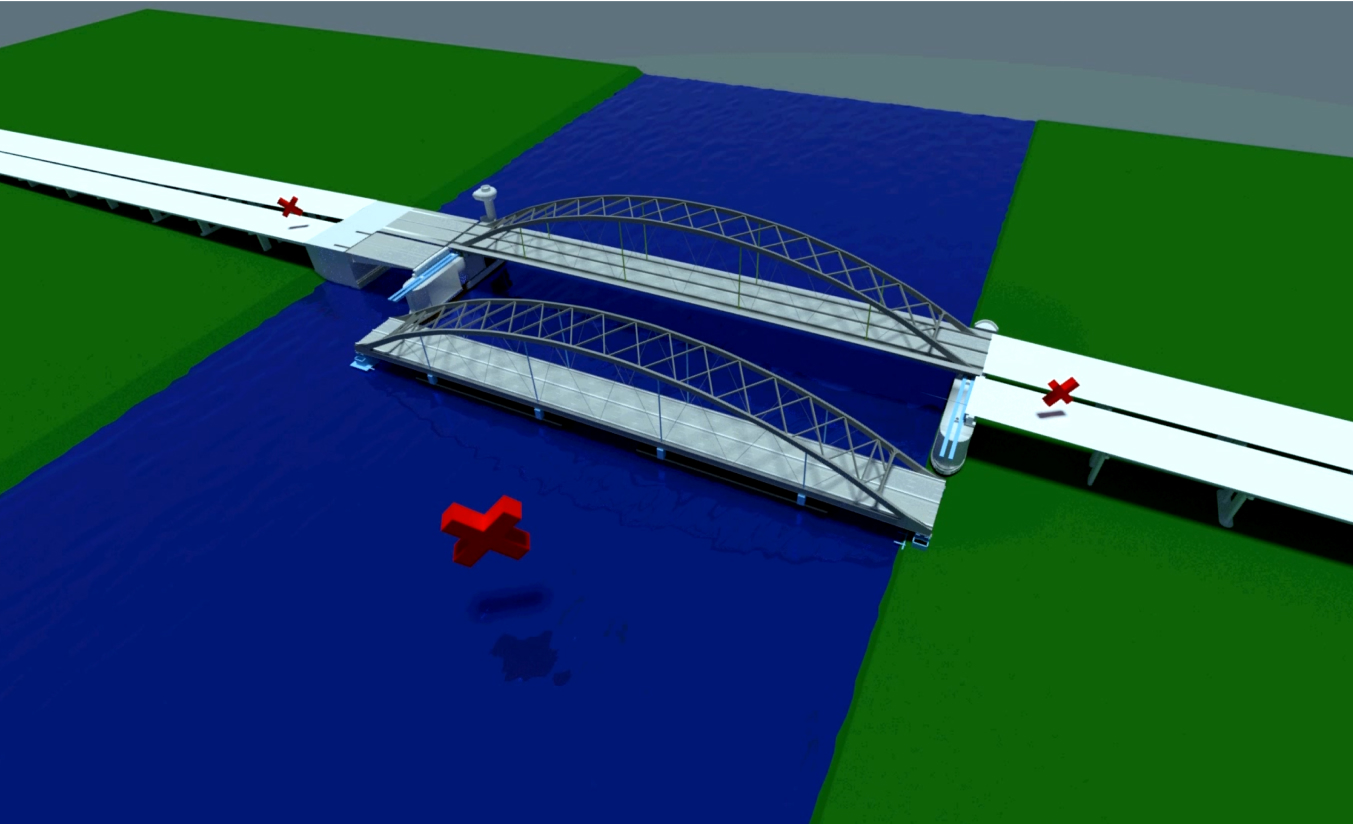

“You have to trust your feelings and I knew we hadn’t yet developed the right plan,” explains Daan. Then he had a eureka moment. Why not take out the eastern bridge – the older half – and replace with the newer refurbished western bridge. Next, a new bridge structure constructed off site could be installed to replace the western bridge. Daan admits it sounded crazy to swap bridges that are 300m long, but eventually he convinced everyone to go for it.

Embracing circular economy principles, the plan reuses 3,200 tonnes of steel and maintains the bridge in its current form, making it the most sustainable upgrade currently possible.

A circular solution

The re-use of western arch to replace the eastern arch is a safer and more sustainable approach using circular economy principles

Preserving an icon

Daan had to work hard to explain the potential of his idea, but within Arup, support came quickly. “This is the reason I love Arup,” he added. “Most engineering firms are focused purely on finishing a contract, but we really want to understand the problem. If anyone has a better solution, people at Arup will love it. And I admire our client for recognising that this solution was the right one, because they took a risk, too.”

It’s also good news for the local community. The Van Brienenoord Bridge is a national icon, seen as a world-leading engineering marvel when it was first built in the 1960s, and its place is now secured for another century.

“ I admire our client for recognising that this solution is the best one. Because they took a risk, too.”

Daan Tjepkema

Project Manager

The future is flexible

Construction begins in 2025, will add 100 years of life to both halves and will close the bridge completely for six weeks, rather than a partial closure for 1.5 years. Building on the success of this renovation programme, we have created a new Netherlands-based Arup team dedicated to bridges, working with colleagues globally to share insights, analytical skills, and data-gathering technology.

Team leader Sabine Delrue says design needs to take a more sustainable approach. For long-span structures, the focus should be on maintaining, reusing, and renovating. For the smaller and less complex, it’s about flexibility, reusing elements and finding standard parts that can be prefabricated, taken out individually and replaced. “This is the future of bridges,” she says.